Leave Your Message

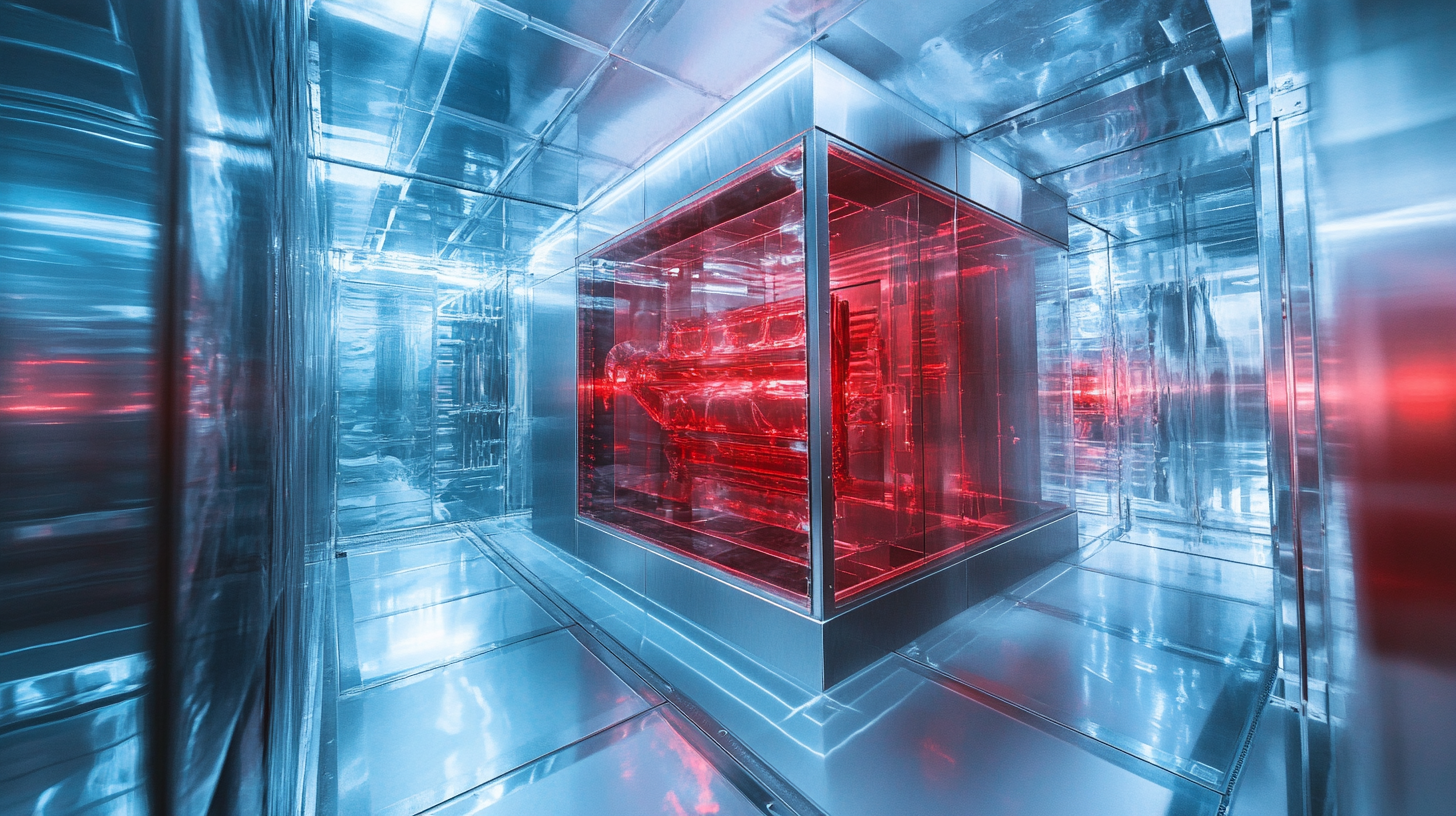

In recent years, the emergence of the "China Vacuum Static Box" has transformed the landscape of various global markets, offering unmatched quality and efficiency. According to a report by Market Research Future, the global vacuum packaging market is expected to reach a value of $40 billion by 2025, driven by the increasing demand for extended shelf life and product preservation in industries such as food, electronics, and pharmaceuticals. The introduction of innovative solutions like the China Vacuum Static Box not only addresses these market needs but also sets new standards in packaging technology, ensuring that products are safeguarded from external contaminants while maintaining their integrity. As companies aim to enhance operational efficiency and reduce waste, the China Vacuum Static Box emerges as a pivotal player, promising superior performance that significantly benefits manufacturers and consumers alike.

In recent years, the emergence of the "China Vacuum Static Box" has transformed the landscape of various global markets, offering unmatched quality and efficiency. According to a report by Market Research Future, the global vacuum packaging market is expected to reach a value of $40 billion by 2025, driven by the increasing demand for extended shelf life and product preservation in industries such as food, electronics, and pharmaceuticals. The introduction of innovative solutions like the China Vacuum Static Box not only addresses these market needs but also sets new standards in packaging technology, ensuring that products are safeguarded from external contaminants while maintaining their integrity. As companies aim to enhance operational efficiency and reduce waste, the China Vacuum Static Box emerges as a pivotal player, promising superior performance that significantly benefits manufacturers and consumers alike.

In today's rapidly evolving manufacturing landscape, vacuum static boxes have emerged as critical components that enhance production efficiency and product quality. These sophisticated systems create an airtight environment, preventing contamination and ensuring optimal conditions for sensitive processes like semiconductor fabrication and pharmaceutical production. According to a recent industry report by MarketsandMarkets, the vacuum packaging market alone is projected to reach $30.9 billion by 2025, highlighting the growing dependence of various sectors on advanced vacuum technology.

Incorporating vacuum static boxes allows manufacturers to significantly reduce waste and improve yield rates. For instance, studies show that utilizing vacuum technology can improve shelf life for perishable goods by up to 30%, illustrating the importance of these systems in food processing. Moreover, in electronics manufacturing, the precision offered by vacuum static boxes helps minimize defects, which can account for losses of up to 5% of total production costs.

Tip: To maximize the benefits of vacuum static boxes, ensure regular maintenance and calibration are part of your operational routine. This practice not only prolongs equipment life but also ensures that the environmental controls remain effective, leading to consistently high-quality outputs. Another tip is to evaluate the integration of vacuum technology in your supply chain; aligning processes with vacuum static boxes can reduce contamination risks and streamline operations.

The vacuum static box industry has seen a paradigm shift with the introduction of high-quality standards that set suppliers apart in a competitive global market. Key indicators of supplier quality are essential for manufacturers looking to ensure excellence in their products. These include material durability, precision in manufacturing processes, and rigorous compliance with international safety standards. Companies that prioritize these indicators are not only able to enhance their product offerings but also gain the trust of their customers and stakeholders.

Another crucial aspect of supplier quality is the ability to innovate while maintaining consistency in production. Suppliers who invest in advanced technologies and regularly upgrade their equipment tend to produce vacuum static boxes that meet, or even exceed, industry benchmarks. Additionally, customer service and support also play a vital role; suppliers that provide technical expertise and readily assist with inquiries are invaluable partners for businesses seeking to optimize their manufacturing processes. Ultimately, focusing on these key quality indicators allows suppliers to thrive in the evolving vacuum static box market.

In today’s competitive landscape, leveraging industry certifications is crucial for identifying top suppliers in the vacuum static box market. Certification from recognized bodies such as ISO (International Organization for Standardization) and ASTM (American Society for Testing and Materials) ensures that suppliers adhere to high-quality manufacturing standards. For instance, a recent report by MarketsandMarkets estimated the global vacuum packaging market size to reach $41.0 billion by 2025, emphasizing the growing demand for reliable suppliers.

Tips for finding reputable suppliers include checking for certifications that demonstrate compliance with international standards. Look for suppliers who feature certifications in their marketing materials or websites, as this indicates their commitment to quality and safety. Additionally, requesting compliance documents can provide insight into their manufacturing process and quality control methods.

Choosing suppliers with recognized certifications not only enhances your product's credibility but also reduces risks associated with quality issues. As per a study by Grand View Research, quality assurance measures can improve customer satisfaction rates significantly, by up to 30%. When selecting suppliers, prioritize those with proven track records in industry certifications to ensure you are partnering with the best in the business.

| Supplier Location | Industry Certification | Production Capacity (Units/Year) | Quality Rating (Out of 100) | Years in Business |

|---|---|---|---|---|

| Beijing, China | ISO 9001, CE | 50000 | 95 | 10 |

| Shanghai, China | ISO 14001, RoHS | 75000 | 92 | 15 |

| Guangzhou, China | ISO 45001, CE | 60000 | 90 | 8 |

| Shenzhen, China | ISO 9001, UL | 80000 | 93 | 12 |

| Hangzhou, China | ISO 13485, CE | 55000 | 91 | 7 |

In the rapidly evolving world of vacuum static boxes, benchmarking performance has become crucial for manufacturers and suppliers seeking to establish dominance in the global market. A comparative analysis of top suppliers reveals significant variances in quality, reliability, and pricing, which ultimately influence the final product's effectiveness. By examining the strengths and weaknesses of different suppliers, organizations can make informed choices that align with their operational needs.

China's innovative approach to vacuum static box production stands out as a key differentiator. With advances in technology and strict quality control measures, Chinese manufacturers are quickly gaining a reputation for unmatched quality, outpacing competitors from other countries. This shift not only enhances the performance of vacuum static boxes but also drives down costs, benefiting industries that rely on these products. By continuously assessing supplier performance against global benchmarks, businesses can leverage these insights to optimize their supply chains and improve product offerings.

The production and sourcing of vacuum static boxes are undergoing transformative shifts, driven by advancements in supply chain management that prioritize efficiency and quality. As manufacturers look to optimize their processes, integrating smart technology and data analytics has become essential.

These innovations enable real-time monitoring and forecasting, ensuring that materials are sourced responsibly and delivered on time. With a focus on lean manufacturing principles, companies are minimizing waste while maximizing output, resulting in a more streamlined production cycle.

These innovations enable real-time monitoring and forecasting, ensuring that materials are sourced responsibly and delivered on time. With a focus on lean manufacturing principles, companies are minimizing waste while maximizing output, resulting in a more streamlined production cycle.

Furthermore, collaboration between suppliers and manufacturers is becoming increasingly vital. By fostering strong partnerships, businesses can enhance their supply chain resilience and flexibility. This cooperative approach supports better risk management, allowing companies to swiftly adapt to market fluctuations.

As the global demand for high-quality vacuum static boxes rises, the emphasis on sourcing sustainable materials is also gaining traction, reflecting a growing awareness of environmental responsibility in production practices. This trend not only enhances product quality but also aligns with consumer preferences for sustainable solutions in the marketplace.